We share our key learnings from a recent visit to a vertical farm.

Key points

- We believe that vertical farming has a credible role to play in future food production and the potential to address a number of challenges faced by modern agriculture.

- The ability to control growing conditions allows for improved crop yields at the same time as reducing negative externalities.

- Environmental benefits include removing the need for pesticides, reducing the use of fertiliser and eliminating the environmental damage from runoff into waterways, as well as reducing water consumption.

- Dedicated renewable energy generation is essential to making this a sustainable food proposition.

When people think about vertical farming, often what comes to mind is the image of a wall of lettuce leaves in a hip city-centre location, or perhaps an efficient warehouse that can supply directly to retailers without the environmental impacts associated with transporting produce across the world. It was therefore somewhat surprising when I arrived at a new UK-based vertical farming facility and found myself on a farm, in an area with no observable space constraints. The concept, it turns out, has less to do with the proximity to the end consumer, and more to do with controlling the growing environment. We believe that agriculture and food systems are key areas that we need to address to start living within safe environmental boundaries on Earth. The opportunity to learn about what innovations are being worked on to solve the food system challenge was the motivation for inspecting a vertical farm in person.

What does a vertical farm look like?

In order to enter the farm, there is a two-stage airlock procedure: first, an initial room to remove outdoor clothing and shoes, and then a second room to put on a white suit, wellies and a hair net, to prevent insects from getting into the farm. A key advantage of indoor farming is that there is no need for pesticides, which can cause significant harm to the environment. Pesticide use has been linked to drops of more than 70% of insect biomass in Germany, the halving of farmland bird populations in Europe, and global declines in pollinators.1

By growing agricultural produce in a controlled environment, and eliminating the use of these chemicals, there are clear environmental benefits, and, in addition, the crops do not need to be washed. Conventionally grown salad is washed in chlorine baths, deteriorating the leaves and diminishing the shelf life. Moreover, on a typical farm, produce can be left wilting on the back of a tractor for up to 45 minutes, whereas in a vertical farm, the time from cutting to transferring the produce to dry cold storage is only a couple of minutes. The combination of these two factors means that vertically grown produce can last up to 14 days; this is a game changer for bagged salad, which typically has a shelf life of two to three days in the consumer’s home, but when vertically farmed, can last up to seven days.

Photo above shows the conventional washing process which is not required in a vertical farm.

The layout inside the farm that I visited has two rows on either side of the room, reaching approximately 15 metres tall, and there is enough space down the centre for a robotic lifting mechanism to manoeuvre and handle the crops. There are 1,000 trays of produce in the building, each with its own LED lighting, as well as a dedicated water supply. Each factor that affects the plants, including air temperature, humidity and nutrient content of the water, is controllable within this environment.

When a tray (approximately four metres by two metres in size) is ready for harvesting, which is around 28 days from the time of planting for rocket leaves, the robotic lifting equipment removes the tray from the rack and lowers it so that the leaves can be trimmed. The tray can then be put back on the rack to regrow up to about five times, or if the roots have become too established (and therefore the flavour is too strong), the tray is moved to a separate re-seeding room. A robot empties the tray and then a hopper sorts the clay bedding granules from the roots, washes the equipment and re-seeds the tray. The new seeds sit on a water-soluble paper and are then sprayed with mist to initiate the growth process and to help the root formation to occur. After this, the seeds are watered and the soluble paper dissolves, leaving the roots to attach to the clay granules.

Water

Freshwater availability is becoming a major global issue. Agriculture accounts for roughly 70% of global freshwater withdrawals and is the primary source of nutrient runoff from farm fields.2,3 Groundwater contributes to 44% of irrigated food production worldwide and, globally, an estimated 14% to 17% of food produced with use of groundwater relies on unsustainable mining of groundwater resources.4 To put this into perspective, Lake Mead, a Colorado River reservoir, is roughly 143 feet (44 metres) below its normal capacity, a deficit that is about the height of the Statue of Liberty.5 The production of one kilogram of tomatoes in a field in southern Europe uses between 60 and 200 litres of water, whereas in a vertical farm, producing the same amount of tomatoes requires only two to four litres of water.6

The amount of water used in conventional farming is not the only issue; the surface runoff of nutrients back into waterways has caused large-scale eutrophication (the nutrient over-enrichment of freshwater and coastal ecosystems). This is an issue that affects 97% of the Baltic Sea, owing to excessive past and present inputs of nitrogen and phosphorus.7

In the indoor controlled environment, 96% of water goes directly into growing the produce, with minimal wastage, and there is no runoff of nutrients, thereby ensuring that the nutrient content of food can be managed. The Haber-Bosch process, which is used to produce nitrogen, produces about 1% of global CO2 emissions,8 and more than 50% of human-caused nitrous oxide emissions come from agriculture – the main driver of which is nitrogen fertilisers.9 Therefore, by minimising nutrient runoff and reducing the need for fertiliser, this could potentially contribute towards reduced greenhouse-gas emissions.

Why is the farm vertical?

The obvious advantage of vertical farms is space efficiency; however, more importantly, this structure enables optimum air circulation and automation efficiency. At the farm that I visited, the plan is for the next version to use smaller individual modules, rather than to scale up in one vast warehouse – the reason being that the air circulation is easier to control in smaller units, as is limiting issues such as insects entering the facility. A four-acre vertical farm operation is equivalent to 1,000 acres of British farmland, and to satisfy the current bagged salad market in the UK, it would take just 46 vertical farming sites. In fact, the total global bagged salad market supply could be produced by only 1,436 sites.10

Cost competitive

In the UK, produce that is domestically produced is valued by consumers, and for a retailer to be able to claim 100% vertically farmed bagged salad, for example, would help build its environmental credentials. Weather instability is increasingly an issue for retailers and customers when it comes to securing supplies, and offtake agreements for crops tend to be short in nature; however, given that vertical farming is not exposed to the same weather risks, there is the potential to enter into multi-year agreements where many of the costs of key variables are fixed.

The cost base for a vertical farm is approximately 80% electricity, 15% labour and 5% inputs.11 If the electrical component can be secured off-grid through a combination of renewables and storage, a large proportion of the cost can be fixed. Way et al, from the Smith School of Enterprise and the Environment at Oxford University, suggest that current consensus expectations for the cost declines in solar photovoltaics (PV) could be too conservative when modelling for the rate of innovation.12 If this is the case, the main cost component of vertical farming may continue to fall, making vertical farming increasingly cost competitive over time.

Where is vertical farming likely to take off first?

One of the key ingredients for a vertical farming operation is abundant zero-carbon electricity generation; there must be access to off-grid wind, solar and battery storage to ensure a low fixed-cost supply of power. At the farm that I visited, for every 1km2 of vertical farming site, two hectares of off-grid solar power are required, so an urban location is not an option for this type of farm.

Given that clean energy is a key criterion, France would be well positioned, as it has a large nuclear generation fleet combined with strong renewable penetration in the south, as well as geographical access to the central European consumer market. In addition, Quebec has the lowest cost grid electricity in the world, provided by hydro power, and it is also well-located to supply the north-east of the US, and take share from Californian production which is increasingly climate-challenged. North Africa would also be a beneficiary of this technology; however, political instability in the region is likely to make attracting the required investment more difficult, and it is instead likely to be the Arab states that see investment in vertical farming first.

What is the future for vertical farming?

It is clear from the facility that I visited, which at the time was the largest in the UK, that the market is nascent and there is significant scope for scientific innovation. Vertical farming is currently focused on high-value salad crops, and this is expected to expand to fruits next, but ultimately it has the potential to broaden to wheat, soy and even rice. The UK is one of the only countries that currently permits gene editing of crops, attracting global investment to the John Innes Centre, which specialises in plant science, genetics and microbiology. With increased investment into agriculture, we expect to see greater funding to advance vertical farming, as well as the development of crop strains that are perfectly suited to this type of farming.

Many of the resiliencies that need to be built into the seeds used in conventional farming to protect plants from challenging conditions such as wind, drought and floods are not necessary in a controlled environment, so there is significant potential to enhance yields. Picture a rice stalk, which in a traditional farm setting needs to have the strength to take the weight of the rice and withstand adverse weather conditions. In a vertical farm environment, the plant could be edited to have a far higher density and a shorter stalk.

Is vertical farming the answer?

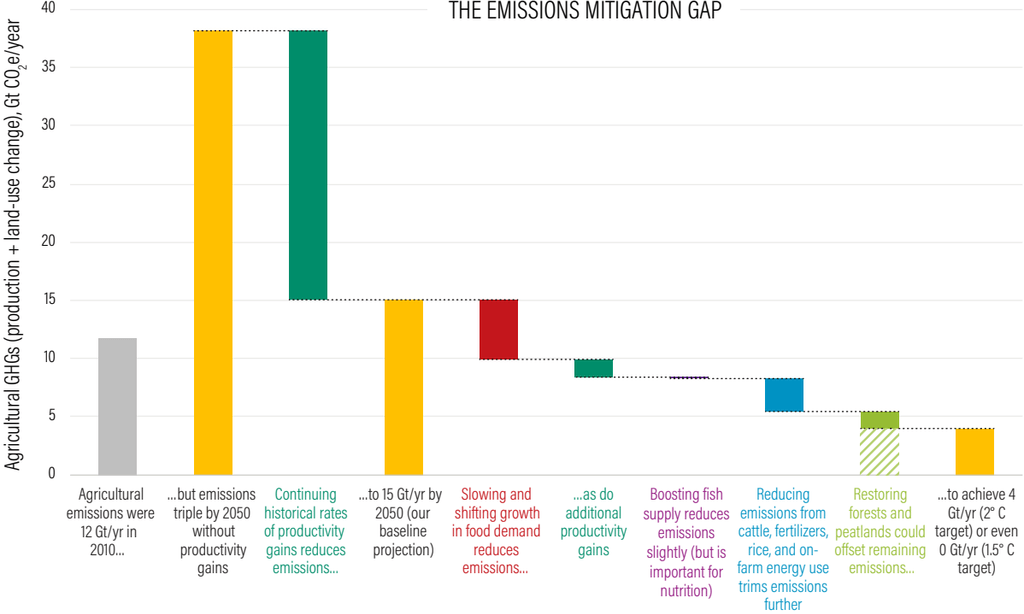

Vertical farming is still in its infancy and will be unlikely to replace land farming on any time horizon, however it is likely to play an increasingly important role in the innovation of agriculture and contribute towards the decarbonisation of the food industry. The graph below shows that, according to the World Resources Institute, half of the reduction in greenhouse-gas emissions from agriculture will need to come from productivity gains, which vertical farming would be well positioned to provide.13

Source: World Resources Report: Creating a Sustainable Food Future (Final Report). 2019.

We believe that vertical farming will play a role in future food production as it will become more economically viable and address a number of challenges faced by modern agriculture; however it is likely to only be a small part of a sustainable food system. There are many crops that would not be suitable for vertical farming, such as tall plants, trees or those with large roots. Transporting food across the world is not necessarily the wrong thing to do; energy used to move food by sea is relatively low, and in return we obtain important nutrients from produce grown in countries with the right natural conditions. We also recognise that, done correctly, agriculture can enrich soil and improve its carbon storage. Vertical farming has scope for significant investment opportunities over the coming decades, as does land-based agriculture, if we are to transition to a sustainable food system.

Sources:

- Brühl CA and Zaller JG Biodiversity Decline as a Consequence of an Inappropriate Environmental Risk Assessment of Pesticides. Frontiers in Environmental Science. 2019.

- FAO. The future of food and agriculture – Trends and challenges. 2017.

- M Selman and S Greenlach Eutrophication: Sources and Drivers of Nutrient Pollution. World Resources Institute. 2009.

- CGIAR Research Program on Water, Land and Ecosystems (WLE). Building resilience through sustainable groundwater use. Colombo, Sri Lanka: International Water Management Institute (IWMI). CGIAR Research Program on Water, Land and Ecosystems (WLE). 12p. (WLE Towards Sustainable Intensification: Insights and Solutions Brief 1). 2017.

- Rachel Ramirez, Pedram Javaheri and Drew Kann, The shocking numbers behind the Lake Mead drought crisis, CNN, 17 June 2021.

- Economist Impact, World Water Day: Can vertical farms help solve a water crisis?, accessed 22 June 2022.

- J. Kotta et al. Cleaning up seas using blue growth initiatives: Mussel farming for eutrophication control in the Baltic Sea. Science of the Total Environment. December 2019.

- Leigh Krietsch Boerner, Industrial ammonia production emits more CO2 than any other chemical-making reaction. Chemists want to change that, Chemical & Engineering News, 15 June 2019.

- Daisy Dunne, Nitrogen fertiliser use could ‘threaten global climate goals’, Carbon Brief, 7 October 2020.

- Fischer Farms presentation, 2022.

- Fischer Farms presentation, 2022.

- Way et al, Empirically grounded technology forecasts and the energy transition, Institute for New Economic Thinking, 14 September 2021.

- T. Searchinger, R. Waite, C. Hanson, J. Ranganathan, P. Dumas & E. Matthews. World Resources Report: Creating a Sustainable Food Future (Final Report). 2019.

This is a financial promotion. These opinions should not be construed as investment or other advice and are subject to change. This material is for information purposes only. This material is for professional investors only. Any reference to a specific security, country or sector should not be construed as a recommendation to buy or sell investments in those securities, countries or sectors. Please note that holdings and positioning are subject to change without notice. Newton manages a variety of investment strategies. Whether and how ESG considerations are assessed or integrated into Newton’s strategies depends on the asset classes and/or the particular strategy involved, as well as the research and investment approach of each Newton firm. ESG may not be considered for each individual investment and, where ESG is considered, other attributes of an investment may outweigh ESG considerations when making investment decisions.

Comments